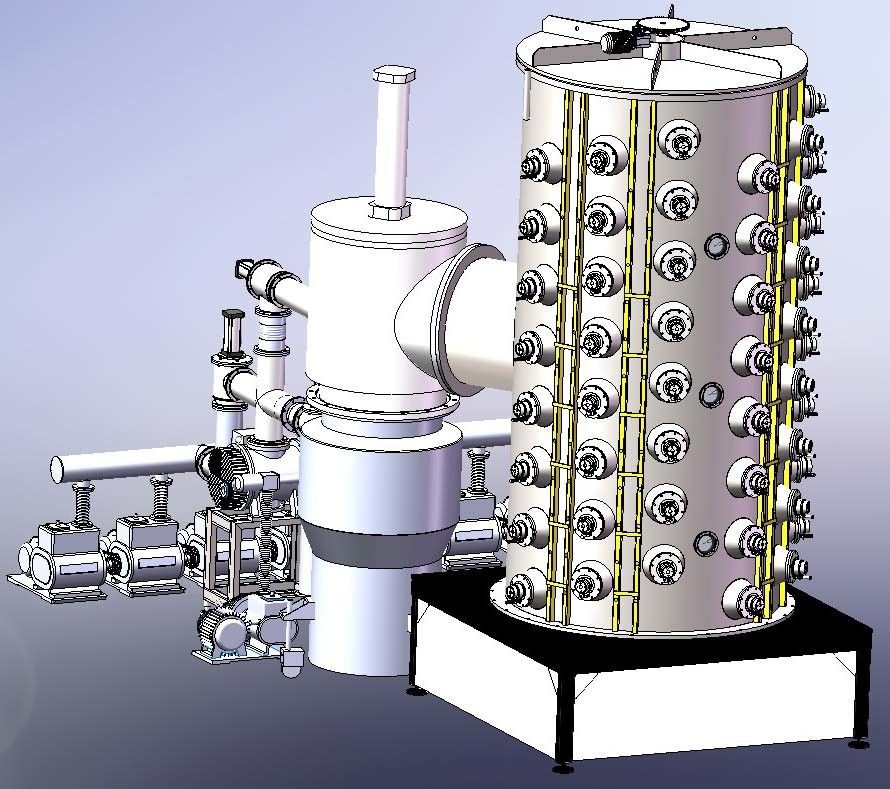

InHouse PVD Coating Equipment New Vacuum Coating Machines

PVD is an excellent vacuum coating process for the improvement of wear and corrosion resistance. It is highly required for functional applications, such as tools, decorative pieces, optical enhancement, moulds, dies, and blades. These are just a few examples of a wide range of already well-established applications [33,34,35]. The equipment used.

PVD Vacuum Coating System with Advanced Technology and Environmental

Physical Vapor Deposition Coating (PVD) is the vacuum chamber coating process we use most often. The part to be coated is placed inside a vacuum chamber. The solid metal material that will be used as the coating is vaporized under vacuum.

ABS parts TiN Gold PVD Vacuum Coating Machine , Cathodic Arc Decorative

Vapor deposition coating technology - Any technology that results in the formation of solid coating materials on solid surfaces as a result of the specific exploitation of the gaseous, vapor, or plasma states.. CVD (chemical vapor deposition) - Coating deposition and formation as a result of gaseous phase reactions and/or pyrolysis. PVD (physical vapor deposition) - Coating deposition.

PVD Chrome Plating Process, UVPVD Vacuum Coating Solutions

PVD coating process (in practice) comprises the following steps: • Cleaning tools and components • Creating vacuum • Charging • Sputtering with argon gas • Coating • Heating up to process temperature •

InHouse PVD Coating Equipment Vacuum Coating Machine

PVD stands for Physical Vapor Deposition. PVD Coating refers to a variety of thin film deposition techniques where a solid material is vaporized in a vacuum environment and deposited on substrates as a pure material or alloy composition coating.

Multi Arc PVD Vacuum Coating Machine For Metal Products

PVD coating, also known as thin-film coating, uses a vacuum chamber to vaporise a solid and deposit it onto a target substrate, atom by atom. The result is an extremely thin, extremely pure coating from a technique that is more environmentally friendly than many other coating technologies [1]. The PVD coating process occurs under vacuum.

PVD Titanium Nitride Vacuum Coating Plating Equipment ARC series

Physical Vapor Deposition (PVD) is a vacuum coating process that involves transforming a material from a condensed solid phase to a vapor phase and then back to a condensed, thin film phase.

TiCN Pvd Vacuum Coating Machine , CrC true Black color decoration

Evaporation Deposition: In the 1930s, Irving Langmuir and his colleagues developed the concept of evaporation deposition, where a material is heated to its evaporation point and then condensed onto a substrate in a vacuum chamber. This marked the beginning of PVD coating techniques.

Rose Gold PVD Vacuum Coating Machine , Large Stainless Steel Pipes PVD

The TiAlCrSiYN-based family of PVD (physical vapor deposition) hard coatings was specially designed for extreme conditions involving the dry ultra-performance machining of hardened tool steels.

Diamond Like Carbon DLC PVD Vacuum Coating Machine /

Physical vapor deposition ( PVD ), sometimes called physical vapor transport ( PVT ), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers.

Stainless steel sheets pvd vacuum coating machine YouTube

Here are all the steps of this vacuum coating process: Step 1: The air is vacuumed so the vacuum chamber has low pressure. Step 2: The material used for plating is placed into the vacuum chamber. Step 3: High voltage creates a plasma discharge (negative charge).

PECVD Optical Films Multipurpose PVD Coating System

Physical Vapor Deposition - also known as PVD Coating or Thin Film - refers to a variety of deposition techniques where solid metal vaporizes in a high vacuum environment. Then it deposits on electrically conductive materials as a pure metal or alloy coating.

SS304 PVD Vacuum Coating Machine With Diffusion Pump

PVD (Physical Vapor Deposition) vacuum coating is a process of creating a thin film on a substrate by using a vacuum chamber. The process involves evaporating the desired material, which condenses onto the substrate to create a coating. This coating is used in various applications, such as in the aerospace, automotive, and electronic industries.

Application And Operation Of PVD Vacuum Coating Machine News IKS

BryCoat uses an advanced PVD (Physical Vapor Deposition) process in a vacuum chamber to deposit thin film hard coatings. Substrate parts are inspected upon arrival. Parts are cleaned in a proprietary multi-stage cleaning process to remove soils, oils, fingerprints and produce an oxide free surface. After cleaning, the substrates are mounted.

SS Bullets Vacuum Bottle PVD Vacuum Coating Machine / TiN gold hard

Vacuum coating - Physical vapor deposition PVD. Our PVD plant enables us to vaporize metals (e.g. Al, Cr, Ti) and oxides (e.g. Al 2 O 3, MgO, SiO X) and deposit these on web-shaped substrates. These thin functional layers have a thickness in the nano-range (less than 100 nm) and are applied to films ad paper.

Bipolar Plates Pvd Vacuum Coating Machine, Tantalum Sputtering Coating

PVD (Physical Vapor Deposition) coating is a highly advanced surface protection technique that offers a wide range of benefits and applications. This guide aims to provide a comprehensive understanding of PVD coating, from its basic principles to its various types, applications, and advantages. Table of Contents